Our Crafting Process

At Golden Touch Jewellery, all of our rings are custom and made-to-order. This means your ring is made uniquely for you, designed and crafted for you and to perfectly suit your taste. Read about our custom engagement ring process below to learn more about how each ring is designed and crafted.

Stage 1: Virtual Consultation

To begin, one of our jewellery designers will meet with you on a virtual video conference. Working with the designer you will have the opportunity to create a bespoke design for your engagement ring. Our expert designers will answer any questions you have in relation to the process and walk you through the various styles and options, as well as the potential costs. After this briefing session the designer will begin working on the designs for your ring.

Virtual Consultation

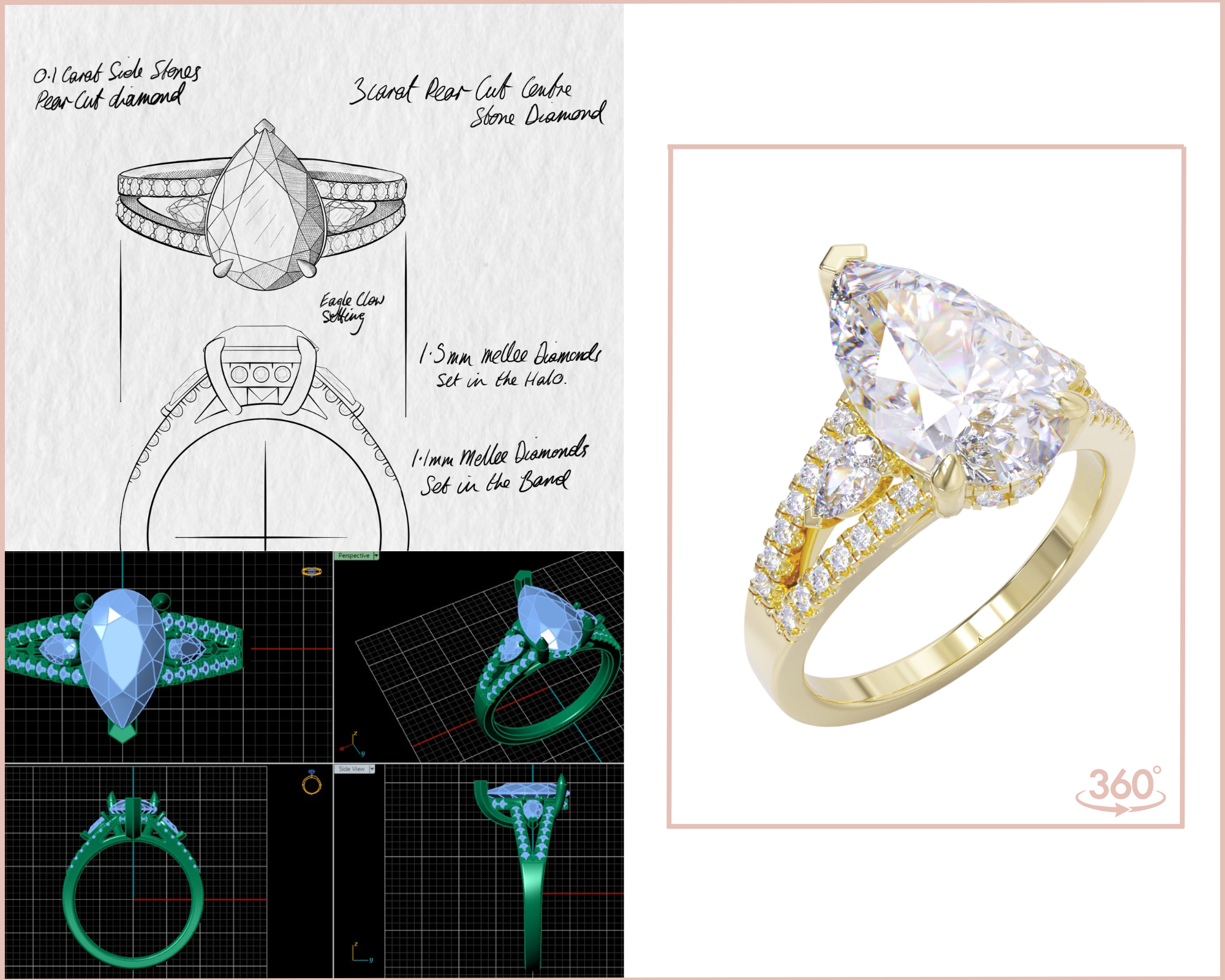

Stage 2: Sketch and 3D Design

After you provide our designer with your brief, they will begin by creating a detailed sketch according to your request. Once the design is completed, you will have a chance to review it and provide any feedback or changes you’d like made. Once those changes are applied, we create a 3D model of your ring and send you a HD 360° video render for your approval. Once you approve the final design we move on to the next stage: casting.

Sketch, 3D Model and Rendering

Stage 3: Casting

Using the 3D model of your design, our designer creates a wax mould using a 3d printer. These printers allow for a high degree of detail in our designs and create a perfect mould of the ring every time. A plaster-like substance called the “investment” is then poured over the mould and is heated in a kiln. The wax melts and runs out of the mould, leaving behind a cavity in the exact shape of your design.

The chosen precious metal is then heated and poured into the mould creating the cast.

Casting Rings

Stage 4: Polishing and Setting

Your ring us now refined and polished to bring it to a mirror finish. This is achieved by polishing and buffing the ring, bringing it from a rough cast to a smooth shining finish.

Your chosen diamonds are then set into the metal by one of our jewellers.

Your ring is now ready!

Polishing the Ring and Setting the Stones

Stage 5: Quality Control

Your ring will be closely inspected by the jeweller to ensure everything is top quality including the setting of the diamond. if the ring is made in white gold it will also receive rhodium plating at this stage which gives it a bright silver-white finish. The ring will also receive one final clean and polish to ensure everything is bright and sparking before your receive your delivery.